parts of rfid inlay This guide will discuss the basic knowledge, application areas, customization needs and advantages of RFID Inlays to help users fully understand this innovative technology and provide strong support when choosing RFID solutions. Once you have the RFID reader hooked up to the PC, and the driver installed, you should be able to start the ICTransfer.exe utility, then connect it to the RFID reader (Menu\Set (P)\PortSet then Menu\Set (P)\Connect), then .Just dip or tap to pay. Be ready for every sale with Square Reader for contactless and chip. .

0 · wet rfid vs dry inlay

1 · rfid vs wet inlays

2 · rfid tags for zebra printers

3 · rfid lost freight labels 4x6

4 · rfid labels for zebra printers

5 · rfid inlays means

6 · rfid inlay manufacturers

7 · rfid catalog

The device itself is used to read and write amiibos for Nintendo 3DS. The NFC reader/writer is for 3DS's that do not come with an NFC reader/writer installed. Systems that come with the NFC .

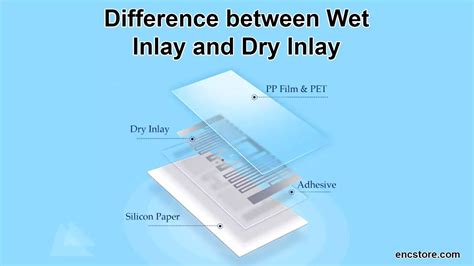

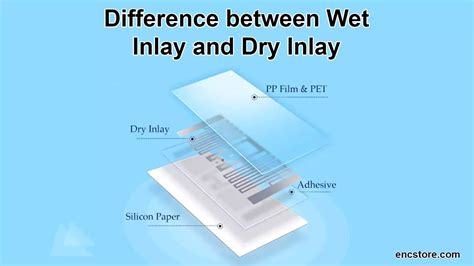

This guide will discuss the basic knowledge, application areas, customization needs and advantages of RFID Inlays to help users fully understand this innovative technology and provide strong support when choosing RFID solutions.Delve into the technical aspects of RFID Dry Inlays and RFID Wet Inlays. Understand their s. An RFID inlay is the basic building block of an RFID tag. It consists of an antenna, a microchip, (which are the key components that allow the tag to transmit and receive data) .

This guide will discuss the basic knowledge, application areas, customization needs and advantages of RFID Inlays to help users fully understand this innovative technology and provide strong support when choosing RFID solutions. An RFID inlay is the basic building block of an RFID tag. It consists of an antenna, a microchip, (which are the key components that allow the tag to transmit and receive data) and a substrate which is a thin layer that holds the antenna and chip together. An RFID inlay consists of three separate components. Antenna; Chip; Substrate . The RFID antenna serves as the "ears" of the tag, allowing it to track and "catch" RF signals being emitted from an RFID reader. The RFID chip is the part of the inlay that makes decisions while also providing the memory needed to store data. A substrate is the part . An RFID tag has a protective/printable facestock, then a layer of adhesive, then the RFID inlay, then another layer of adhesive, and finally a removable liner. The RF inlay provides the RFID functionality. The inlay consists of a carrier sheet that holds an RF antenna, to which is bonded a tiny microchip.

RFID (radio frequency identification) inlays are essential components in RFID technology, used in various applications such as tracking inventory, managing supply chains, and contactless payments. Here's an overview of the RFID inlay manufacturing process.

wet rfid vs dry inlay

An inlay consists of an IC, an antenna, attached to the substrate. Typically, the substrate does not have an adhesive. The inlays are supplied on a reel of continuous web and are used by label makers, also called converters, to embed RFID functions into labels. An RFID inlay is the functional part of an RFID label. The inlay can be used alone by simply attaching it to the target asset. Dry inlays lack adherent, and you’ll be required to get an external adherent to fix it in place. To get an RFID Label, you must have an .Antenna. - RFID antennas are the distinctive coiled or looped section of the inlay. - Antennas are usually made of conductive materials like copper or aluminum. They can also be printed onto your label or inlay using conductive ink. - Radio waves activate the antenna from a . Radio Frequency Identification (RFID) is a technology that uses a radio wave to identify an object. An RFID inlay consists of three main parts. These parts are the IC, which stores data and follows commands. The antenna absorbs RF waves and sends out signals.

Delve into the technical aspects of RFID Dry Inlays and RFID Wet Inlays. Understand their specifications, applications, and key differences to make an informed choice for your RFID solution.

rfid vs wet inlays

This guide will discuss the basic knowledge, application areas, customization needs and advantages of RFID Inlays to help users fully understand this innovative technology and provide strong support when choosing RFID solutions. An RFID inlay is the basic building block of an RFID tag. It consists of an antenna, a microchip, (which are the key components that allow the tag to transmit and receive data) and a substrate which is a thin layer that holds the antenna and chip together.

An RFID inlay consists of three separate components. Antenna; Chip; Substrate . The RFID antenna serves as the "ears" of the tag, allowing it to track and "catch" RF signals being emitted from an RFID reader. The RFID chip is the part of the inlay that makes decisions while also providing the memory needed to store data. A substrate is the part .

An RFID tag has a protective/printable facestock, then a layer of adhesive, then the RFID inlay, then another layer of adhesive, and finally a removable liner. The RF inlay provides the RFID functionality. The inlay consists of a carrier sheet that holds an RF antenna, to which is bonded a tiny microchip. RFID (radio frequency identification) inlays are essential components in RFID technology, used in various applications such as tracking inventory, managing supply chains, and contactless payments. Here's an overview of the RFID inlay manufacturing process.

An inlay consists of an IC, an antenna, attached to the substrate. Typically, the substrate does not have an adhesive. The inlays are supplied on a reel of continuous web and are used by label makers, also called converters, to embed RFID functions into labels. An RFID inlay is the functional part of an RFID label. The inlay can be used alone by simply attaching it to the target asset. Dry inlays lack adherent, and you’ll be required to get an external adherent to fix it in place. To get an RFID Label, you must have an .Antenna. - RFID antennas are the distinctive coiled or looped section of the inlay. - Antennas are usually made of conductive materials like copper or aluminum. They can also be printed onto your label or inlay using conductive ink. - Radio waves activate the antenna from a .

add smart health card to apple wallet

Radio Frequency Identification (RFID) is a technology that uses a radio wave to identify an object. An RFID inlay consists of three main parts. These parts are the IC, which stores data and follows commands. The antenna absorbs RF waves and sends out signals.

altec lansing smart security camera not recording on sd cards

rfid tags for zebra printers

Make sure that NFC is enabled on the device and that it has an NFC tag nearby. Run the app and bring the NFC tag close to the device. You should see a toast message with the tag ID displayed .

parts of rfid inlay|rfid lost freight labels 4x6