rfid tag injection moulding William Frick & Co., in the United States, also makes tags that can withstand injection-molding (see William Frick & Co.’s Gen 2 UHF Tags Take the Heat for Manufacturing Apps). Tadbik . Read and Write NDEF Messages to NFC tags with Arduino. This one does not: GitHub - JohnMcLear/Ndef: NDEF Library for Arduino. 1 Like. Related Topics Topic Replies .The NFC antenna on your smartphone may be located differently depending on the brand and model you have. Below, you'll find links to the manufacturers' websites where you can find more helpful information. If you have any questions about NFC technology, feel free to reach out to .

0 · rfid injection molding

1 · injection molding plastic parts

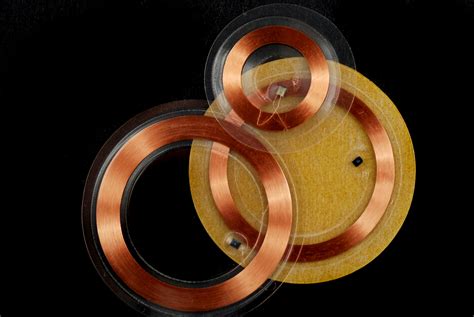

An NFC tag is a small integrated circuit consisting of a copper coil and some amount of storage. Data can be read or written to this tag only when another NFC device is brought near it because it .

William Frick & Co., in the United States, also makes tags that can withstand injection-molding (see William Frick & Co.’s Gen 2 UHF Tags Take the Heat for Manufacturing Apps). Tadbik .

Explore how RFID technology enhances plastic injection molding by improving tracking, and performance in harsh environments. Plastic manufacturing solutions for clients in California, .

rfid injection molding

injection molding plastic parts

I have not heard of any businesses that have a special process enabling them to embed a tag in plastic without fist encapsulating it. Back in 2003, Rafsec (now UPM Raflatac) .William Frick & Co., in the United States, also makes tags that can withstand injection-molding (see William Frick & Co.’s Gen 2 UHF Tags Take the Heat for Manufacturing Apps). Tadbik .Explore how RFID technology enhances plastic injection molding by improving tracking, and performance in harsh environments. Plastic manufacturing solutions for clients in California, . I have not heard of any businesses that have a special process enabling them to embed a tag in plastic without fist encapsulating it. Back in 2003, Rafsec (now UPM Raflatac) .

Thanks to a new engineering resin and proprietary injection overmolding technique, Xtreme RFID in Grand Rapids, Mich., is producing one-piece, fully encapsulated .RFID tags can be insert molded into various shapes to fit your specific applications such as custom containers, tags, plugs, threaded caps, buttons or any other part that needs to be . RFID tags can also be positioned at any place on an article, or partially or fully integrated in plastics. The most common process to produce plastic disposable diagnostic and . Applications are growing for embedding RFID tags and other radio-frequency devices in plastic parts via insert injection molding. A presentation on “Challenges in .

With the use of two giveaway injection molds, two concepts for overmolding RFID tags could be implemented. It was shown that it is possible to overmold the RFID tags in a single-stage . Molding RFID tags and electronic antennas into plastic parts presents growing opportunities--and challenges. LIM & LSR Molding. Injection Molding. Matthew Naitove. . Utilizing a highly automated 16+16 rotary platen insert mold, the two-shot product design and proprietary manufacturing concept is employed to protect the integrity of the RFID .

William Frick & Co., in the United States, also makes tags that can withstand injection-molding (see William Frick & Co.’s Gen 2 UHF Tags Take the Heat for Manufacturing Apps). Tadbik .Explore how RFID technology enhances plastic injection molding by improving tracking, and performance in harsh environments. Plastic manufacturing solutions for clients in California, . I have not heard of any businesses that have a special process enabling them to embed a tag in plastic without fist encapsulating it. Back in 2003, Rafsec (now UPM Raflatac) .

Thanks to a new engineering resin and proprietary injection overmolding technique, Xtreme RFID in Grand Rapids, Mich., is producing one-piece, fully encapsulated .RFID tags can be insert molded into various shapes to fit your specific applications such as custom containers, tags, plugs, threaded caps, buttons or any other part that needs to be . RFID tags can also be positioned at any place on an article, or partially or fully integrated in plastics. The most common process to produce plastic disposable diagnostic and . Applications are growing for embedding RFID tags and other radio-frequency devices in plastic parts via insert injection molding. A presentation on “Challenges in .

With the use of two giveaway injection molds, two concepts for overmolding RFID tags could be implemented. It was shown that it is possible to overmold the RFID tags in a single-stage . Molding RFID tags and electronic antennas into plastic parts presents growing opportunities--and challenges. LIM & LSR Molding. Injection Molding. Matthew Naitove. .

Overview. The MCUXpresso SDK provides a driver for the RFID/NFC communication unit. The .

rfid tag injection moulding|injection molding plastic parts